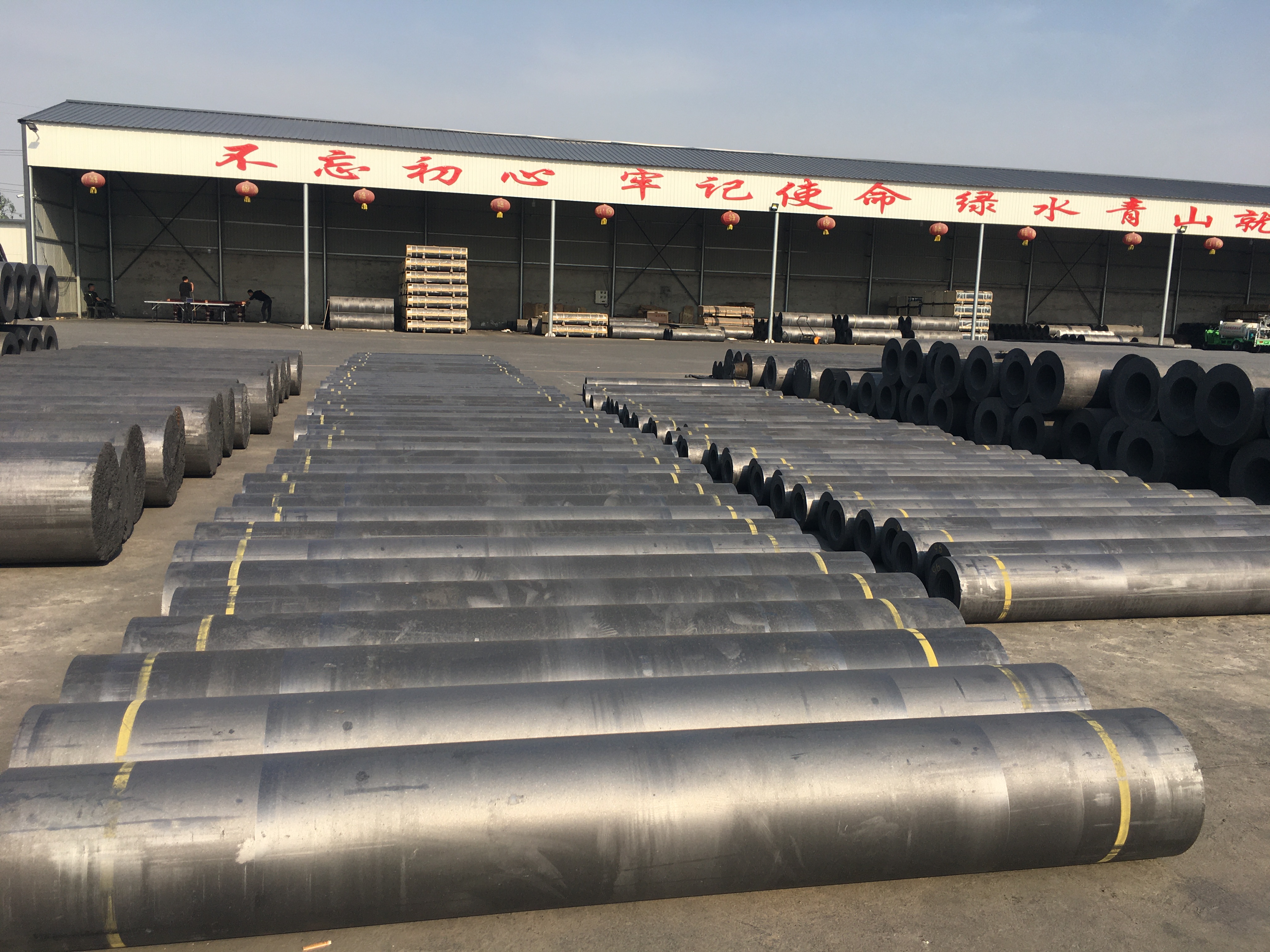

Working temperature has a crucial effect on the consumption of graphite electrodes in electric arc furnaces (EAFs). In this work, temperature distribution within the EAF electrodes during normal operation was simulated using the finite element method in both 2D and 3D scales. The contributions of electrical current passing the electrode, thermal effects of the furnace sidewall refractory, slag layer, a titanium based coating as a protective layer, and the process parameters such as water spraying at the end of the electrodes were investigated. The proximity effect of the graphite electrodes in EAF was analysed using a 3D thermal model. The numerical model was validated against experimental measurements of temperature distribution over the electrode surface as well as the published results in literature. The results showed a relatively deep temperature gradient at the electrode tip. Among the environmental and processing parameters affecting the temperature distribution of the electrode, the heat transfer coefficient in the water cooling zone was found to be more important for predicting the accurate thermal field of the electrode. The value 8500 W m−2 K−1 was proposed for the investigated electrode based on the validated 3D numerical results. The results also indicated the importance of the proximity effect on temperature distribution not being ignored. ao hui carbon company produce the high quality of graphite electrode .

Working temperature has a crucial effect on the consumption of graphite electrodes in electric arc furnaces (EAFs). In this work, temperature distribution within the EAF electrodes during normal operation was simulated using the finite element method in both 2D and 3D scales. The contributions of electrical current passing the electrode, thermal effects of the furnace sidewall refractory, slag layer, a titanium based coating as a protective layer, and the process parameters such as water spraying at the end of the electrodes were investigated. The proximity effect of the graphite electrodes in EAF was analysed using a 3D thermal model. The numerical model was validated against experimental measurements of temperature distribution over the electrode surface as well as the published results in literature. The results showed a relatively deep temperature gradient at the electrode tip. Among the environmental and processing parameters affecting the temperature distribution of the electrode, the heat transfer coefficient in the water cooling zone was found to be more important for predicting the accurate thermal field of the electrode. The value 8500 W m−2 K−1 was proposed for the investigated electrode based on the validated 3D numerical results. The results also indicated the importance of the proximity effect on temperature distribution not being ignored. ao hui carbon company produce the high quality of graphite electrode .

Post time: Jun-15-2020