1. RAW MATERIALS

Coke (approximately 75-80% in content)

Petroleum Coke

Petroleum coke is the most important raw material, and it is formed in a wide range of structures, from highly anisotropic needle coke to nearly isotropic fluid coke. The highly anisotropic needle coke, due to its structure, is indispensable for the manufacture of high-performance electrodes used in electric arc furnaces, where a very high degree of electrical, mechanical and thermal load-bearing capacity is required. Petroleum coke is almost exclusively produced by the delayed coking process, which is a mild slow carbonising procedure of crude oil distillation residues.

Needle coke is the commonly used term for a special type of coke with extremely high graphitizability resulting from a strong preferred parallel orientation of it’s turbostratic layer structure and a particular physical shape of the grains.

Binders (approximately 20-25% in content)

Coal tar pitch

Binding agents are used to agglomerate the solid particles to each other. Their high wetting ability thus transforms the mix into a plastic state for subsequent molding or extrusion.

Coal tar pitch is an organic compound and has a distinct aromatic structure. Due to its high proportion of substituted and condensed benzene rings, it already has the distinctly preformed hexagonal lattice structure of graphite, thus facilitating the formation of well-ordered graphitic domains during graphitisation. Pitch proves to be the most advantageous binder. It is the distillation residue of coal tar.

2. MIXING AND EXTRUSION

The milled coke is mixed with coal tar pitch and some additives to form a uniform paste. This is brought into the extrusion cylinder. In a first step the air has to be removed by prepressing. Than the actual extrusion step follows where the mixture is extruded to form an electrode of the desired diameter and length. To enable the mixing and especially the extrusion process (see picture on the right) the mixture has to be viscous. This is achieved by keeping it at elevated temperature of approx. 120°C (depending on the pitch) during the whole green production process. This basic form with cylindrical shape is known as "green electrode".

3. BAKING

Two types of baking furnaces are in use:

Here the extruded rods are placed in cylindrical stainless steel canisters (saggers). To avoid the deformation of the electrodes during the heating process, the saggers are also filled with a protecting covering of sand. The saggers are loaded on railcar platforms (car bottoms) and rolled into natural gas - fired kilns.

Ring furnace

Here the electrodes are placed in a stone covert cavity in the bottom of the production hall. This cavity is part of a ring system of more than 10 chambers. The chambers are connected together with a hot air circulation system to save energy. The voids between the electrodes are also filled with sand to avoid deformation. During the baking process, where the pitch is carbonized, the temperature has to be controlled carefully because at the temperatures up to 800°C a rapid gas build up can cause cracking of the electrode.

In this phase electrodes have a density around 1,55 – 1,60 kg/dm3.

4. IMPREGNATION

The baked electrodes are impregnated with a special pitch (liquid pitch at 200°C) to give them the higher density, mechanical strength, and electrical conductivity they will need to withstand the severe operating conditions inside the furnaces.

5. RE-BAKING

A second baking cycle, or "rebake," is required to carbonize the pitch impregnation and to drive off any remaining volatiles. Rebake temperature reach almost 750°C. In this phase the electrodes can reach density around 1,67 – 1,74 kg/dm3.

6. GRAPHITIZATION

Acheson Furnace

The final step in graphite manufacture is a conversion of baked carbon to graphite, called graphitizing. During the graphitizing process, the more or less pre-ordered carbon (turbostratic carbon) is converted into a three-dimensionally ordered graphite structure.

The electrodes are packed in electric furnaces surrounded by carbon particles to form a solid mass. An electric current is passed through the furnace, raising the temperature to approximately 3000°C. This process is usually achieved using either an ACHESON FURNACE or a LENGTHWISE FURNACE (LWG).

With the Acheson furnace the electrodes are graphitized using a batch process, while in a LWG furnace the entire column is graphitized at the same time.

7. MACHINING

The graphite electrodes (after cooling) are machined to exact dimensions and tolerances. This stage may also include machining and fitting the ends (sockets) of the electrodes with a threaded graphite pin (nipple) joining system.

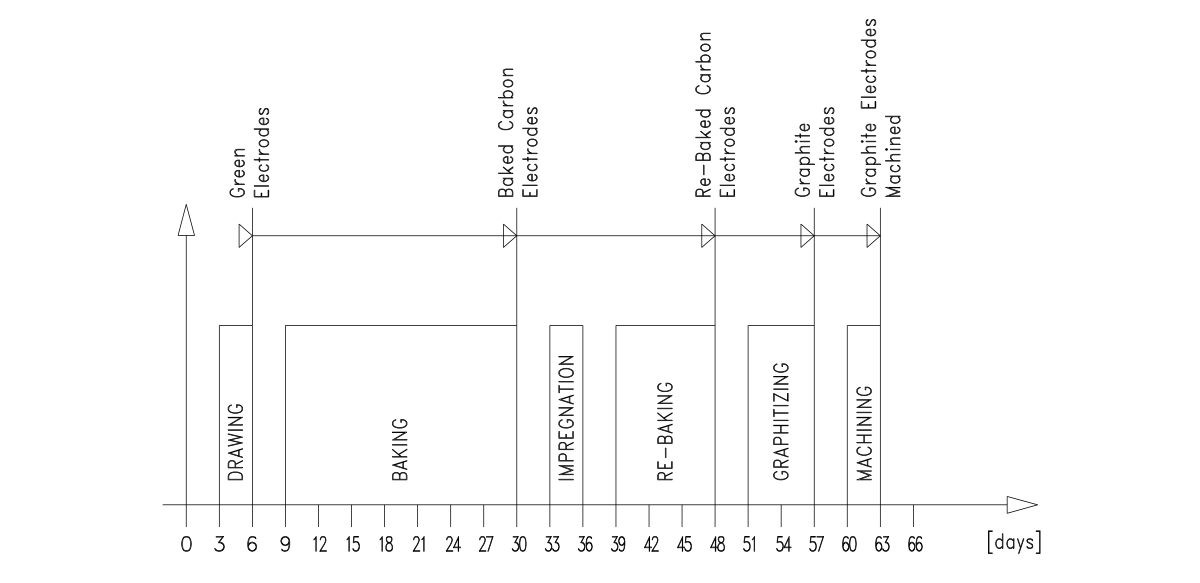

PRODUCTION TIMESCALE

From Mixing to Machining the production of graphite electrodes takes about 60 days as shown in the picture here below:

Post time: Jan-22-2020