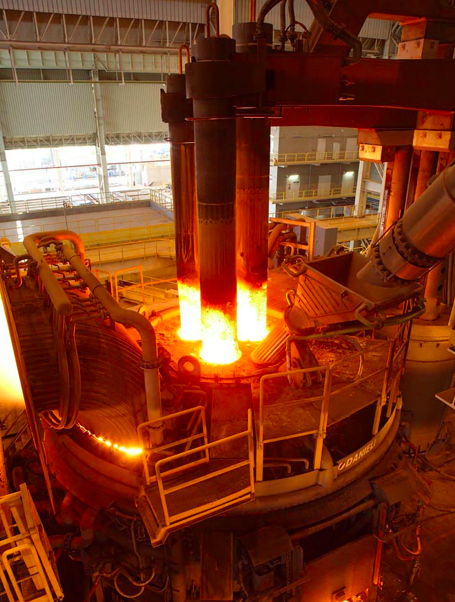

Electrode paste on the consumption of ferroalloy furnace - ao hui carbon company

There are three aspects that affect the consumption rate of graphite electrode.

I. raw materials used in ferroalloy furnace

1. High fixed carbon content, slow consumption.

The higher the fixed carbon content of carbon materials, the lower the ratio of charge, the same quality of ferroalloy products, the less carbon electrode reaction, the slower the electrode consumption.

2. Less carbon, slow electrode consumption.

Less carbon material, less burning loss of carbon material on the material surface, less red material on the material surface, small branch current, large resistance, electrode insert charge deep oxidation slow, electrode carbon less reaction, slow consumption.

3. The lower the ore comprehensive grade, the faster the electrode consumption.

The lower the taste into the furnace, the more ore the production of a ton of products consumed, the process is also more, the electrode paste per consumption is high, fast consumption.

4. The smaller the ore size and the more powder, the faster the electrode consumption.

More small-size material, powder, material surface permeability is poor, red material, electrode furnace depth is shallow, electrode oxidation consumption is fast.

5. Low recovery of charge metal leads to fast electrode consumption.

6. Product grade (electrode paste manufacturer)

The higher the grade of the product, the faster the electrode consumption.

The higher the grade of production products, the higher the ore and electricity consumption consumed by the production of a ton of products, the higher the single consumption of electrode paste, the higher the single consumption of electrode paste, the faster the consumption of electrode paste.

We have great advantages in the production of electrode paste and GRAPHITE ELECTRODE.

Interested partners are welcome to contact us at any time

Ao Hui New Material Technology PTE. LTD. (our company specializes in producing and selling electrode products: electrode paste, sealed paste, graphite electrode, etc.)

Contact person: Jack Si

Telephone: +86 18730046166 (WeChat & WhatsApp)

website: www.aohuicorp.com

Post time: Jun-19-2020