-

Manufacturer for Gpc/Graphitized Petroleum Coke For Foundry - Graphite Petroleum Coke – Aohui

Applications 1.Lower the impurities in the cast iron, 2.Choose the right Graphitized Petroleum Coke recarburizer can lower the casting cost. 3. Graphitized Petroleum Coke Recarburizer is essential auxiliary additives for production of high quality steel . 4.Also it can can be used as additive for produce other product like brake pad used as friction materials; 5.High quality recarburizer is after graphitizing process,under high termperature, the arrangement of carbon atoms in microstru... -

Good Wholesale Vendors Fang Da Carbon - RP GRAPHITE ELECTRODE – Good Electrical Conductivity, Low Consumption – Aohui

DESCRIPTION RP graphite electrodes, referred to moulded columns of graphite, are used as the high temperature conductive material for electric arc furnaces. Regular power graphite electrodes are specified with allowable current density less than 17 A/cm2. The quality of the graphite electrode determines the productivity and cost of EAF steelmaking. As a manufacturer, we also provide UHP grade graphite electrodes and HP grade graphite electrodes for ultra high power or high power electric... -

OEM Factory for High Conductive Electrode - HP GRAPHITE ELECTRODES – the Diameters Range From 200 mm to 600 mm – Aohui

DESCRIPTION HP graphite electrode is the conducting element for electric arc furnaces steelmaking. It is made of petroleum coke, needle coke, coal pitch and produced by a series of strict production processes. High-current lines insert through the graphite electrode port inside the furnace body. This will releases electric energy in the arc furnace to heat the furnace. The demand for the larger diameter electrodes has been increasing as EAF furnace sizes become larger. Graphite electrode... -

Hot New Products Graphite Petroleum Coke As Recarburizer Casting Product - Graphite Powder and Graphite Scarp – Aohui

Graphite Electrode Powder(Graphite Granule) This product is made of the turnings of graphite electrodes, and processed by milling and screening. Graphite electrode scraps (powders) are by products of the process of machining electrodes, mainly used in metallurgy industry as carbon raisers, reducer, foundry modifier, fireproof ect. Content: C: 98.5% min. S: 0.05% max. Ash: 1% max.Moisture: 1% max. Grain Size: 0.5~10 mm 0~2 mm,0~6 mm,1~6 mm,0~10 mm over 25 mm Application: used as carbu... -

OEM/ODM China Graphite Electrode 4tpl T4l In Melting And Refining Furnace - UHP GRAPHITE ELECTRODE – Low Electrical Resistance, High Density – Aohui

DESCRIPTION UHP graphite electrode is used for the recycling of steel in the electric arc furnace industry. Its main ingredient is high-value needle coke which is made from either petroleum or coal tar. Graphite electrodes are finished with a cylinder shape and machined with threaded areas at each end. In this way, the graphite electrodes can be assembled into an electrode column using electrode nipple. In order to meet the requirement of higher work efficiency and lower total cost, larg... -

Good Quality Graphite Carbon Additive - Graphite Petroleum Coke – Aohui

Applications 1.Lower the impurities in the cast iron, 2.Choose the right Graphitized Petroleum Coke recarburizer can lower the casting cost. 3. Graphitized Petroleum Coke Recarburizer is essential auxiliary additives for production of high quality steel . 4.Also it can can be used as additive for produce other product like brake pad used as friction materials; 5.High quality recarburizer is after graphitizing process,under high termperature, the arrangement of carbon atoms in microstru... -

Hot New Products Edm Graphite Cathode Carbon Graphite Block - Graphite Cathode – Aohui

Descriptions Graphite Cathode blocks are produced by and processed by vibrating-molding machine or extrusion die machine. The end item product has features of good compact construction,high strength,heat resistance,sodium corrosion resistance,low heat expansion coefficient and advantage of extending lifetime of the electrolytic cell. Graphite cathode blocks should very low electrical resistivity. PRODUCT: GRAPHITE CATHODE volatile content ash content moisture content ca... -

Top Suppliers Graphite Scrap For Cathode Carbon Block - Graphite Special-shaped Parts – Aohui

Features - Fine grain - Homogeneous structure - High density - Excellent thermal conductivity - High mechanical strength - Proper electrical conductivity - Minimum wettability to molten metals - Hard surface and good flexural strenght - Resistance to chemical erosion and thermal shock. Physical and chemical index Fine-grain Specialty Graphite FXG-1 Fine-grain Specialty Graphite FXG-2 Item Unit Guarantee value Typical value Guarantee value Typical value Max grain size ... -

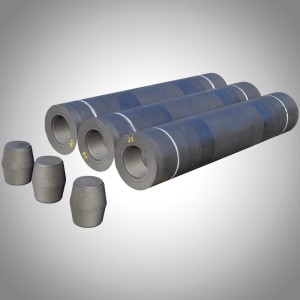

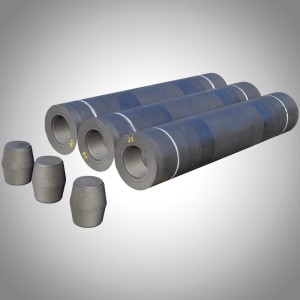

Best quality Graphite Rods - GRAPHITE ELECTRODE NIPPLES – Match With UHP/HP/RP Graphite Electrodes – Aohui

DESCRIPTION Graphite electrodes nipples are used to connect two or more electrodes into column. And the purpose of that is to realize continuous use of electrodes in electric arc furnace steelmaking process. Nipples, with conventional external threads surface, are the important clamping device to extend the electrode length. Doing this avoids the unproductive consumption in smelting. As a technical manufacturer, we know that the mismatch between the graphite electrode body and the nipple... -

High Quality Carbon Additive - Calcined Petroleum Coke – Aohui

Feature High specific resistance and reactivity. Semicoke can increase the daily output by 0.221-0.311t/(d•furnace) while power saving by 537-649kW•h when using with metallurgical coke in the ferrosilicon industry. Suitable particle size. Blacking can be used directly as granular injection material and limited investment on grinding, drying and operation systems. Low sulfur content and SO2 emission. The activated carbon made from semicoke is with rich pores and strong adsorption capacity... -

Wholesale Price China Graphite Electrode For Lrf - RP GRAPHITE ELECTRODE – Good Electrical Conductivity, Low Consumption – Aohui

DESCRIPTION RP graphite electrodes, referred to moulded columns of graphite, are used as the high temperature conductive material for electric arc furnaces. Regular power graphite electrodes are specified with allowable current density less than 17 A/cm2. The quality of the graphite electrode determines the productivity and cost of EAF steelmaking. As a manufacturer, we also provide UHP grade graphite electrodes and HP grade graphite electrodes for ultra high power or high power electric... -

OEM/ODM China Graphite Crucible - GRAPHITE ELECTRODE NIPPLES – Match With UHP/HP/RP Graphite Electrodes – Aohui

DESCRIPTION Graphite electrodes nipples are used to connect two or more electrodes into column. And the purpose of that is to realize continuous use of electrodes in electric arc furnace steelmaking process. Nipples, with conventional external threads surface, are the important clamping device to extend the electrode length. Doing this avoids the unproductive consumption in smelting. As a technical manufacturer, we know that the mismatch between the graphite electrode body and the nipple...